Expertise across diagnostics, medical, and technical manufacturing

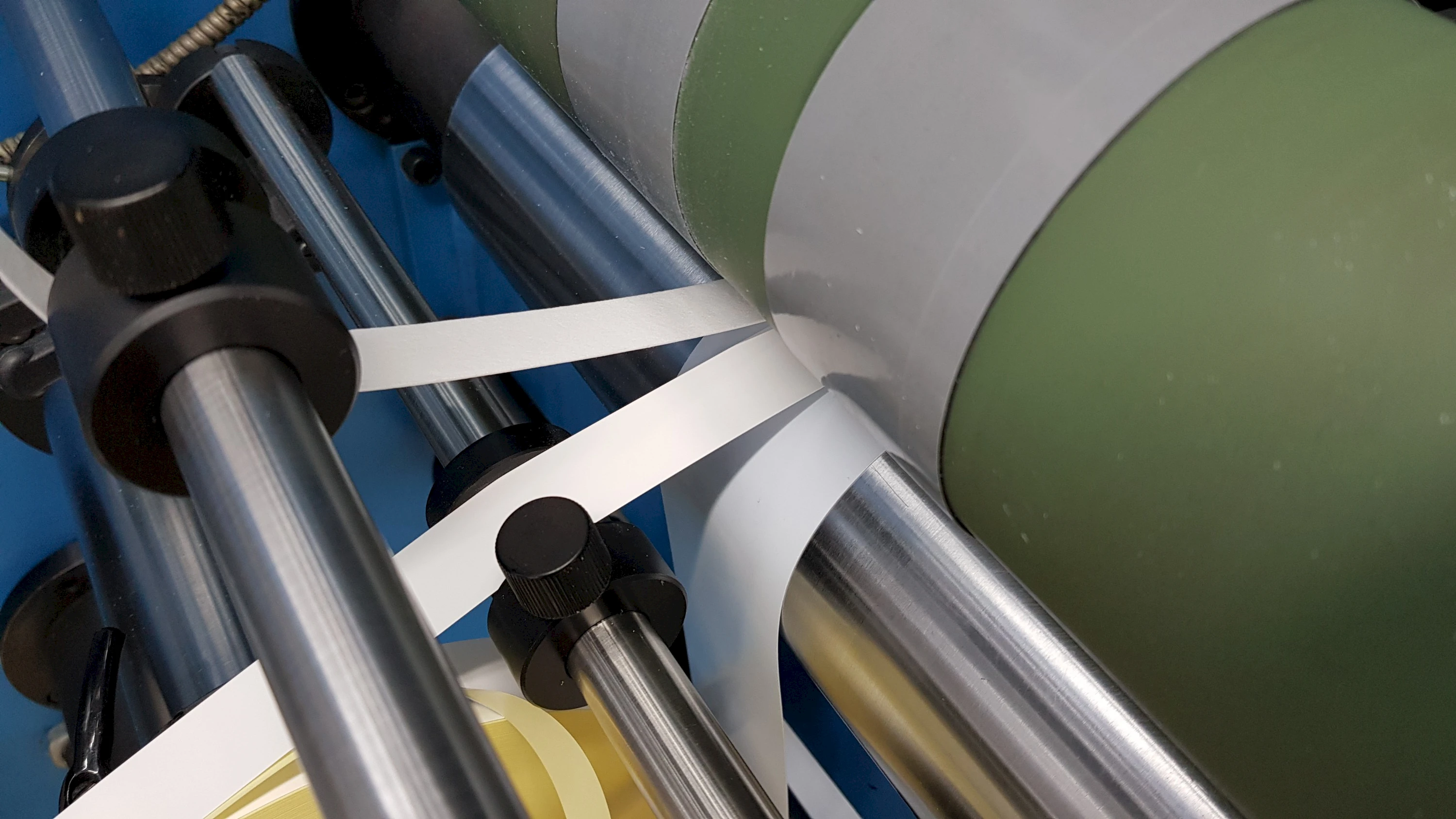

Kenosha’s capabilities cover the complete journey. From high-performance materials to converting, prototyping, and production-scale supply.

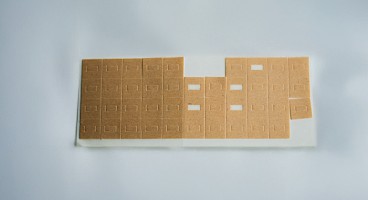

Our multidisciplinary expertise allows us to support customers in diagnostics, medtech, and lab-based innovation with custom-engineered material solutions.