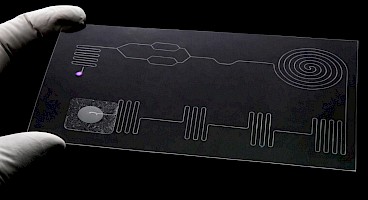

Kenosha offers a full suite of custom manufacturing solutions for diagnostic, medical, and laboratory applications. From laminating and die-cutting to slitting, prototyping, and small-batch production, our in-house capabilities transform raw materials into components that meet exact design and performance requirements.

Our team works alongside OEMs to optimize materials for assembly and performance, supporting projects from initial prototyping to validated production. All under documented quality processes for full traceability.