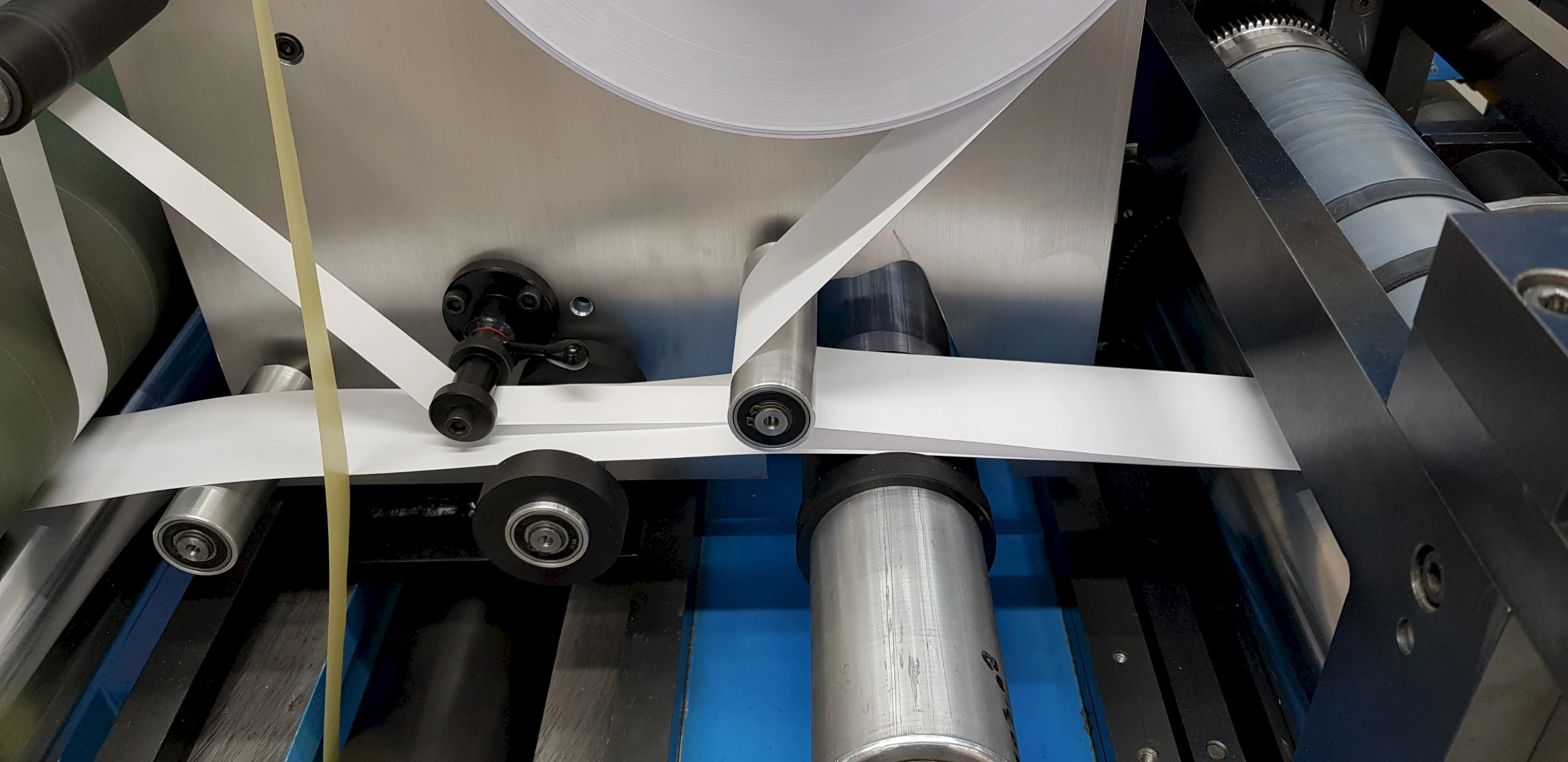

Kenosha provides precision lamination services that transform films, adhesives, foams and membranes into stable and reliable multi layer constructions. Our lamination processes are designed for diagnostic, medical and technical applications where accuracy, cleanliness and consistency are essential. With controlled pressure, uniform adhesive layers and clean room production, we create laminates that support device performance, handling and durability.

What is lamination?

Lamination combines two or more layers under controlled pressure and temperature to create a stable composite with improved handling, protection, or performance characteristics. In diagnostics and medical applications, lamination enhances bond strength, dimensional stability, and chemical resistance, without compromising the material’s functional properties.

Medical applications

Our lamination process is used to:

- Bond membranes, adhesives and backing cards in lateral flow and IVD devices

- Create multi-layer constructions for wearables and wound care products

- Seal or reinforce films and coatings used in lab and microfluidic applications

- Produce prototype laminates for testing or validation before scale-up

Key advantages of Kenosha lamination

- Controlled lamination pressure for uniform adhesive layers

- Bubble-free, distortion-free surfaces

- Compatibility with materials such as PET, PVC, polyurethane, foams and films

- Custom layer configurations tailored to each device design

- Scalable processes from small-batch prototyping to volume manufacturing

Quality & traceability

All lamination processes are conducted under documented quality control procedures and traceable batch records. Each laminate is inspected for adhesion strength, layer uniformity, and surface integrity, ensuring consistent performance across production runs.

Contract Lamination as a standalone service

In addition to laminating our own materials, Kenosha also provides contract lamination services for customer-supplied films, adhesives, or membranes.

Whether you need additional processing capacity or technical expertise for complex laminates, we guarantee the same precision, cleanliness, and reproducibility as for our own products.