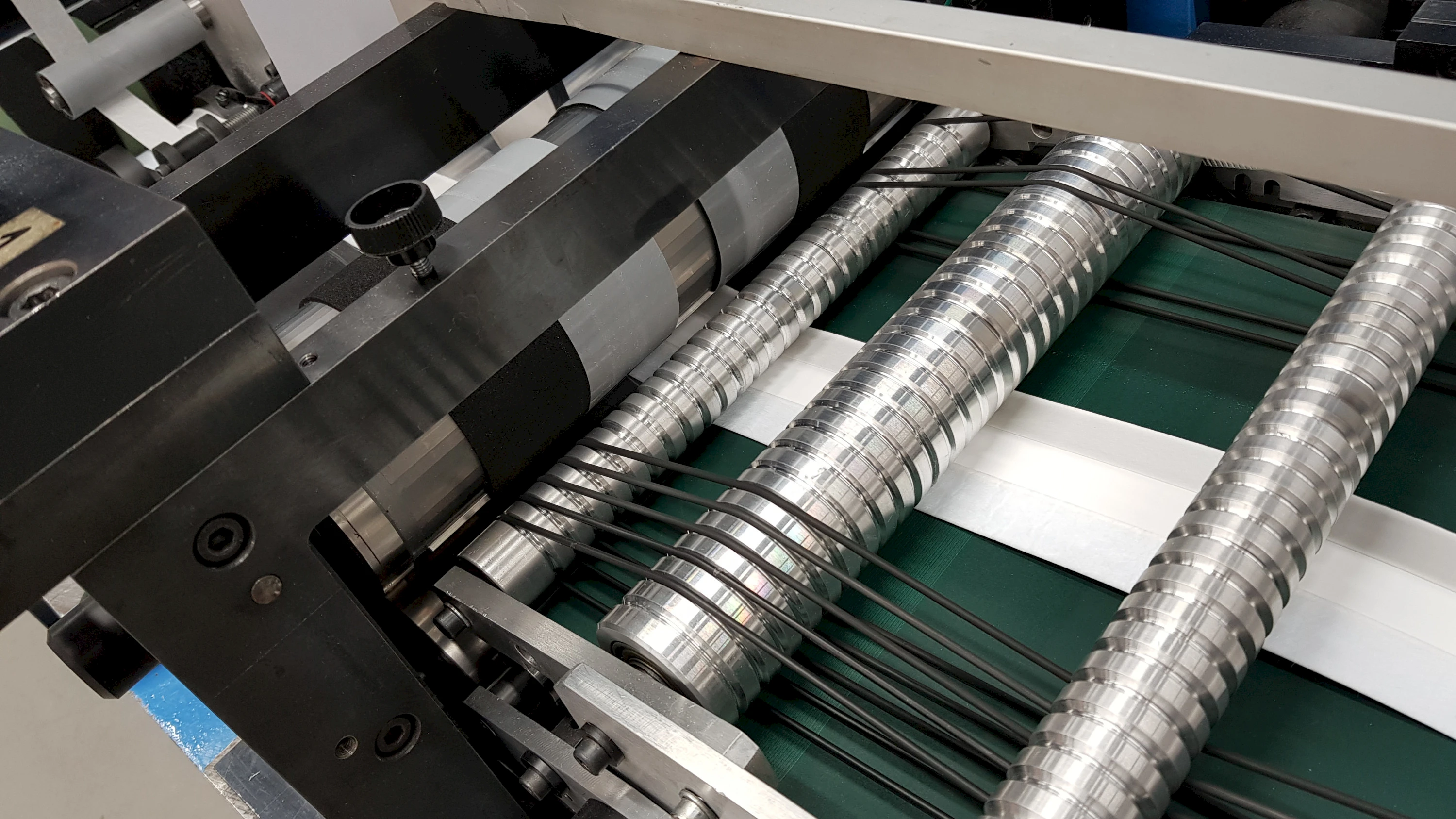

Tight tolerances, clean edges, and perfect alignment. Precision that runs edge to edge. Kenosha provides custom slitting and converting services for films, membranes, adhesives, and foams used in diagnostic, medical, and laboratory applications. Our process ensures dimensional accuracy, smooth edges, and consistent roll quality, ready for automated assembly or manual handling.

What is slitting & converting

Slitting and converting is the process of cutting large rolls or sheets into custom widths or smaller rolls to fit your specific production or assembly process. In medical and diagnostic manufacturing, this ensures exact material fit, efficient handling, and reduced waste, helping streamline your workflow and maintain batch consistency.

Precision slitting and converting applications

Our slitting and converting services are used for:

- Films, membranes and adhesive layers in IVD and lateral flow devices

- Breathable and protective films for medical wearables and patches

- Specialty lab films or coatings for sealing, covering or optical use

- Customer-supplied rolls or laminates that require precision conversion or resizing

Key advantages of Kenosha slitting & converting

- Tight with tolerances for reliable fit and function

- Clean, particle-free edges suitable for medical and diagnostic use

- Consistent roll tension for smooth processing and easy integration

- Custom roll widths, lengths and core sizes on request

- Quick turnaround for both prototype and production quantities

Quality & traceability

All slitting operations are performed under controlled environmental conditions to maintain material integrity. Each roll is inspected for edge quality, roll tension, and dimensional consistency, with batch-level documentation for traceable manufacturing.

Slitting & converting as a standalone service

In addition to processing Kenosha materials, we also offer precision slitting and converting services for customer-supplied rolls or sheets. Our equipment supports a wide range of medical, technical, and industrial substrates, ensuring precise results and repeatable performance, regardless of the material source.