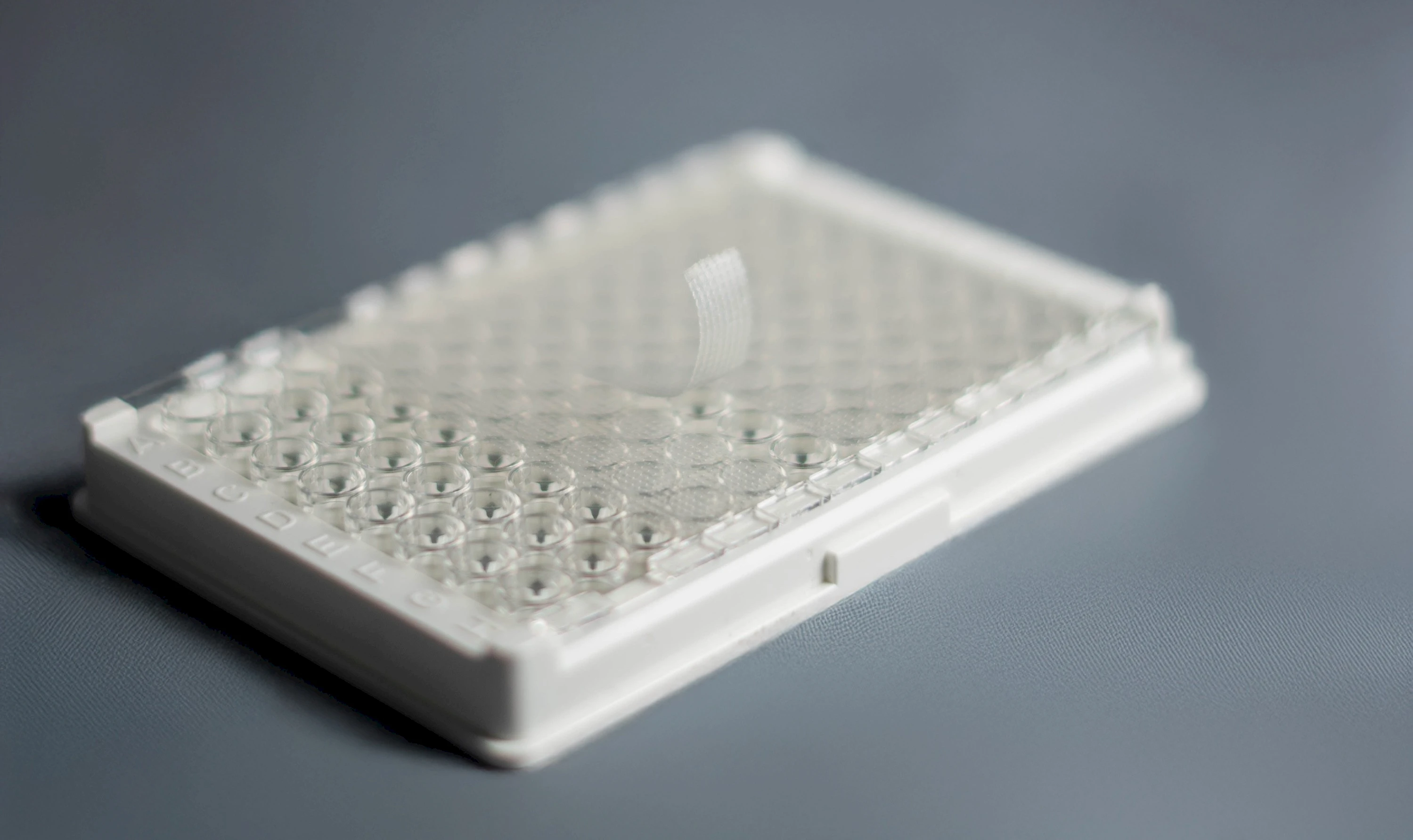

Specialty films & coatings for microtiter plates

Kenosha provides precision-engineered films and coatings designed for PCR, ELISA, fluorescence assays, and high-throughput screening.

Our materials deliver optical clarity, chemical resistance, and tight sealing performance, ensuring reliable and reproducible results in laboratory workflows.

Microtiter plate films applications

In microtiter applications, sealing films play a crucial role in:

- Preventing evaporation or cross-contamination

- Ensuring optical accuracy for detection systems

- Maintaining stable reaction environments

- Protecting samples during thermal cycling

Our films and coatings are engineered for consistent thickness, high stability, and clean processing, even at extreme temperatures.

Material options & performance characteristics

Kenosha offers a wide portfolio of technical sealing films and coatings, including:

-

Optical-grade PET and PP films for fluorescence and absorbance assays

-

Pressure-sensitive adhesive (PSA) sealing films for secure plate closure

-

Heat-sealable PCR films for thermal cycling stability

-

Gas-permeable films for cell culture and incubation

-

Aluminum and high-barrier foils for long-term storage

Optional optimizations depending on application

-

Temperature resistance (–80 °C to +120 °C)

-

Optical clarity (fluorescence / absorbance)

-

Chemical resistance to lab reagents

-

Clean die-cutting and automated sealing