What are sample filtration pads?

Sample pads are the first point of contact in a lateral flow assay, controlling how the liquid sample enters the strip. They filter unwanted particles, stabilize pH and salt concentration, and regulate flow rate before the sample reaches the conjugate pad and membrane.

Selecting the right sample pad is critical for achieving consistent flow dynamics, high sensitivity, and reproducible test results.

Why sample pads are critical in lateral flow tests

A well-engineered sample pad:

- Filters and conditions complex samples such as blood, saliva, urine, or swab extracts

- Balances viscosity and ionic strength to maintain optimal assay performance

- Regulates wicking rate for consistent and predictable sample migration

- Prevents clogging and over-saturation of the nitrocellulose membrane

Our IVD-grade sample pads are designed for controlled absorption and uniform capillary flow, ensuring stable and reproducible performance even with challenging biological fluids.

Material options & treatment types

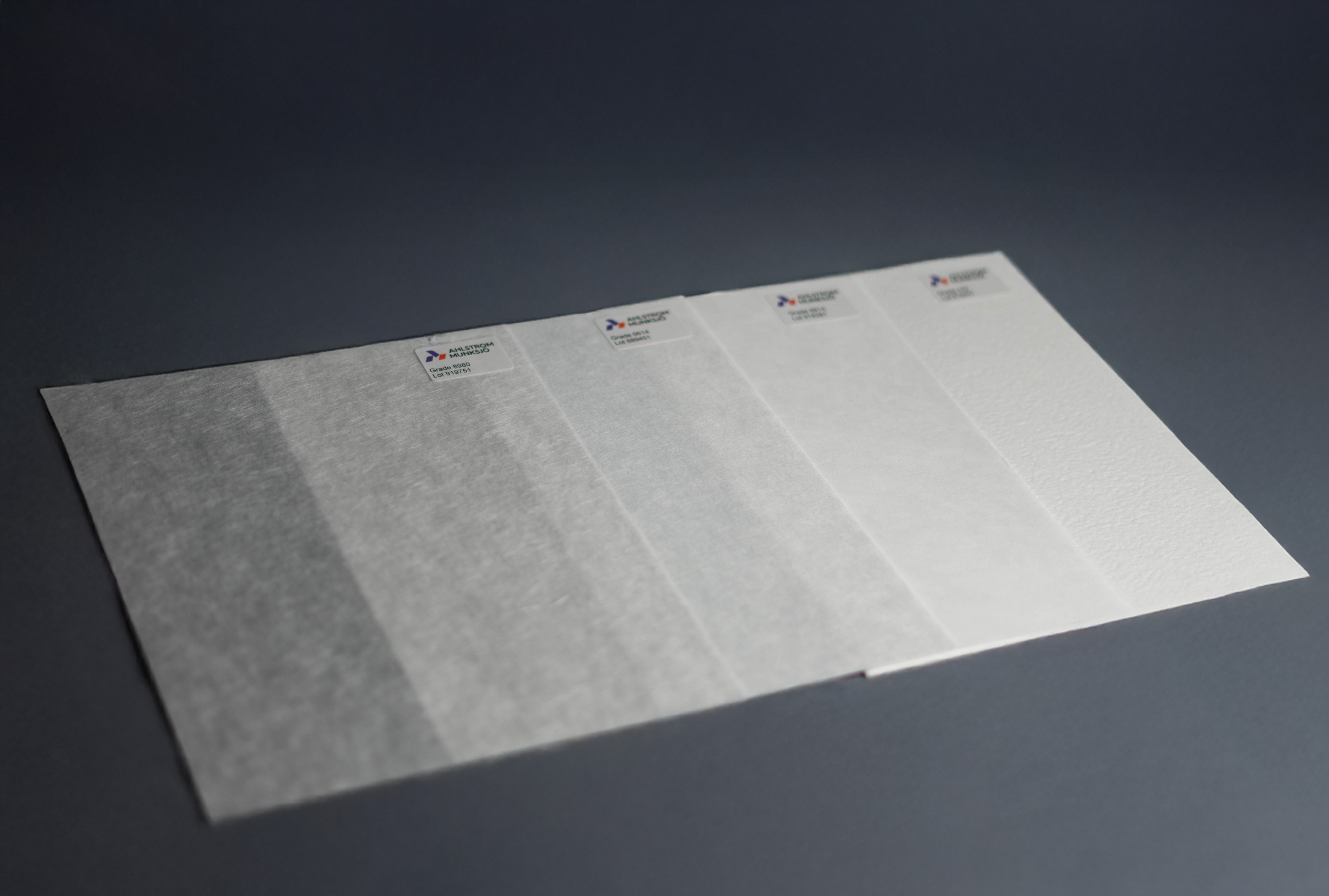

Kenosha supplies a broad range of pads and absorbent materials for lateral flow and IVD applications, including:

- Cellulose, glass fiber, and polyester substrates

- Custom surface treatments to enhance hydrophilicity or enable surfactant loading

- Multiple pore sizes and thicknesses for optimized flow and absorption

- Pre-cut rolls or sheets ready for direct integration into assembly processes

All materials are tested for flow rate uniformity, absorption capacity, and chemical compatibility, ensuring consistent and reproducible performance across production batches.

Custom Sizes and Flow Characteristics

Every assay design has its own requirements. That’s why Kenosha offers:

- Custom-cut pads in any dimension or thickness

- Pre-treated materials with tailored flow rates and absorption properties

- Laminated or adhesive-backed formats for streamlined assembly

- Prototype quantities for early-stage development and validation

Our in-house converting capabilities ensure tight dimensional tolerances, consistent flow behavior, and full batch traceability from R&D through large-scale production.

Quality & Certification

Kenosha operates under a certified ISO 9001:2025 Quality Management System, ensuring consistent quality, documentation, and process control.

All sample and filtration pads are inspected for thickness, porosity, and flow uniformity, and each roll or sheet is produced under controlled conditions with full batch traceability.

Trusted by the Diagnostics Industry

Kenosha’s sample and filtration pads are relied upon by leading lateral flow and IVD manufacturers across Europe. Our focus on controlled absorption, filtration consistency, and strict quality management ensures that every test performs with accuracy and reliability — from early laboratory development to full-scale manufacturing.