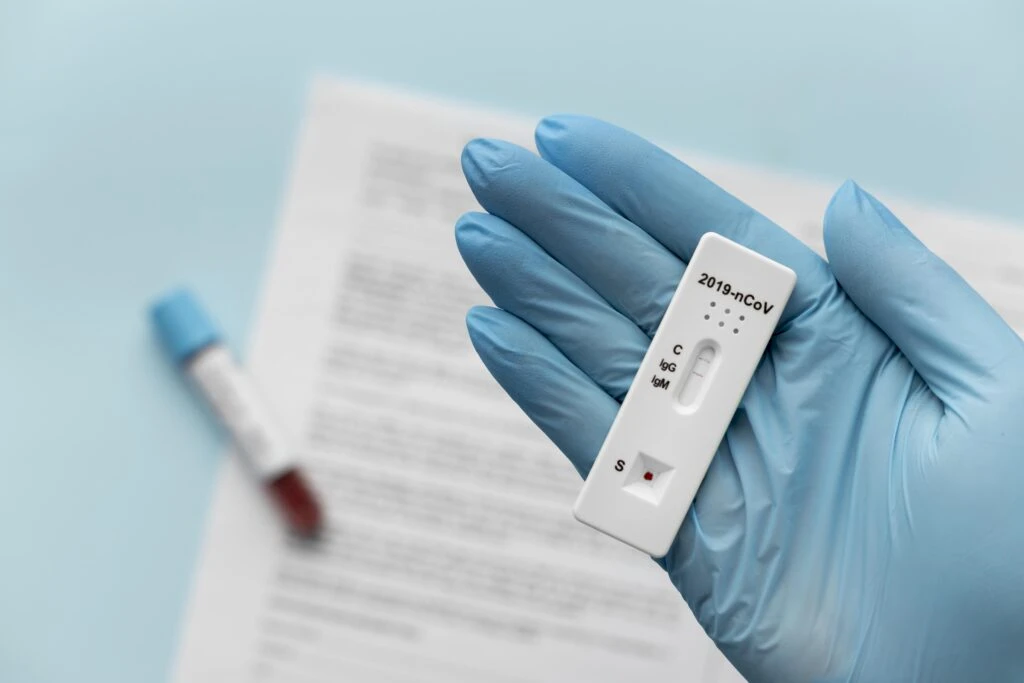

When people think about innovation in medical devices and in-vitro diagnostics (IVDs), their minds often jump to cutting-edge electronics, new biomarkers, or sophisticated software. What often gets overlooked is something much more fundamental: the filter.

Hidden inside a cartridge or tucked into the design of an instrument, filters are rarely the star of the show. But anyone who has ever worked in device development knows how essential they are. The wrong filtration material can halt progress, derail production, or even compromise test results. The right one can quietly enable a product to function flawlessly for years.

That’s where customization becomes critical.

Understanding filtration materials in medical devices

At first glance, a filter sheet seems simple: a thin piece of cotton, glass, or synthetic fibers. But behind that simplicity lies an enormous amount of variability.

Fiber type: Cotton fibers behave differently from glass or synthetic ones.

Strength: Some materials are tough and durable, while others have almost no tensile strength.

Cutting behavior: Certain fibers cut cleanly, others fray or shed particles. Some are so hard they can even damage cutting tools.

Thickness and porosity: These affect not only filtration performance but also how the material interacts with assembly equipment.

In R&D, these differences often only become apparent late in the process. A filter that looks perfect during initial lab evaluations may suddenly break down when scaled into machine processing. The result? Weeks of lab work wasted and timelines pushed back.

The limitations of standard filter sizes

Most suppliers provide filters in standard sheet or roll sizes, often with strict minimum order quantities (MOQs). While convenient at first glance, this creates common challenges for medical device manufacturers:

Forced redesigns of medical devices

Engineers may have to design around available filter dimensions rather than creating the optimal design.

Scaling problems in production

Filters that behave well in lab testing may tear, fray, or shed particles when introduced to automated cutting and assembly systems.

High costs and waste

MOQs may force teams to purchase far more material than needed, or abandon promising options because order sizes aren’t practical.

This shows why standard filter sizes are often unsuitable for device development beyond the earliest prototyping stage.

The advantages of customised filtration materials

Shifting from standardisation to customisation opens up new possibilities for device innovation. Customised filtration materials allow for:

Precision cutting and tolerances

Filters can be cut to exact dimensions, ensuring consistent results and reproducibility.

Improved material handling

Specialised cutting methods reduce fraying, loose fibers, and inconsistent edges.

Customised filter laminates

By laminating multiple filter types into a single composite, developers can combine the best properties of each. For example, one layer may deliver high absorbency while another provides mechanical strength.

Flexible MOQs for R&D and scale-up

Smaller production runs allow innovation without the burden of oversupply, while still scaling smoothly into full production.

With customisation, filtration is no longer a limiting factor. It becomes an enabler of better design.

Real-World example: When standard filters fail

Picture this common scenario: an R&D team identifies a promising filter during early testing. Results are reliable, flow rates are ideal, and handling in the lab is smooth.

But during scale-up, the same filter material begins tearing in the production line. Automated cutting leaves frayed edges. Loose fibers compromise test accuracy.

Suddenly, the project stalls. Weeks or months of development are put at risk, and the team must choose between redesigning the device or starting material selection again.

With a customized filtration material, cut to precise tolerances, reinforced for fragile fibers, or laminated for strength, the transition from lab to production could have been seamless.

Cutting technologies and expertise matter

Working with delicate filtration materials requires more than sharp tools. Fiber hardness, tensile strength, and thickness all influence the cutting process.

Soft fibers need precise, ultra-sharp cutting systems to avoid tearing.

Hard fibers can dull or damage tools, requiring hardened blades or specialized machinery.

Specialised cutting methods ensure clean edges and prevent particle contamination.

This is why experience matters as much as technology. A supplier that has worked with hundreds of filter types (cotton, glass, synthetic, laminated composites) can anticipate challenges before they occur, preventing costly surprises for device manufacturers.